Normally we utilize this kind of pump with several application such as Dissolved Air Floatation Units, High Oxygen Feed Rate-Bioreactors, Algae Removal Units, Oil Separators, Several gas mixing, fPowder or solid dissolved in liquids, etc.

The following is one of the popular application that utilizes the EnviB Microbble Pumps for example:-

The Dissolved Air Flotation (DAF) systems manufactured by AquarA are designed for the removal of suspended solids, oil and grease, heavy metals, BOD, COD and VOCs. Whether it be laundry, textile, food processing or any other industrial process, AquarA can customize a solution to optimize efficiency.

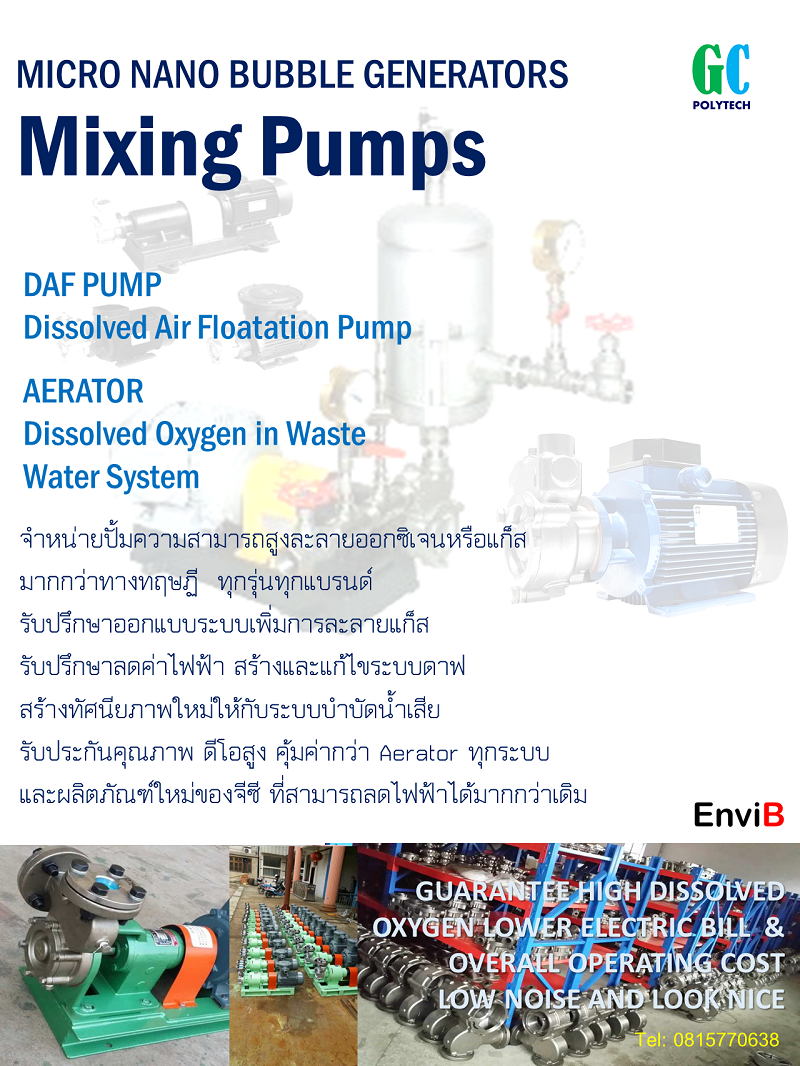

The Air Dissolving System: AquarA uses a unique air dissolving system that manufacturers the maximum amount of dissolved air "white water," maintaining a very small micron bubble size. The air dissolving recirculation loop is skid mounted compactly under the DAF unit. An EnviB Pump, air dissolving pump, creates maximum shearing of air bubbles at very high pressure, which eliminates the need for large air dissolving tanks typical of most DAFs.

Coagulation and Flocculation Zone: The AquarA DAF design utilizes static mixing in a pipe flocculator to achieve coagulation and flocculation. This design eliminates the need for mixing tanks and mixers, which reduces moving parts and maintenance. Each flocculator is custom built to meet the customer's needs.

Dissolved Air Injection: Dissolved air "white water" is injected to many points along the pipe flocculator. This method allows for the white water to be present during the initial coagulation and flocculation and produces higher efficiencies in a smaller design.

Adjustable Discharge Weir: An adjustable discharge weir provides water level control within the unit to give maximum percent solids in the sludge blanket and discharge sludge. Construction Materials Available in both stainless steel and polypropylene construction, quality materials give longevity and durability to each system.

Automation and Controls: AquarA offers a variety of system controls, from fully automated PLC-HMI touch screen controls and automated flow controls to hand operated control and manual flow controls

Chitosan Technology|Green Revolutions|Nano Metal Technology|Organic Farming|Nano Bubble|Green Chemistry

Chitosan Technology|Green Revolutions|Nano Metal Technology|Organic Farming|Nano Bubble|Green Chemistry